SmartPB

SmartPB is offered as a surface pressure barrier to provide absolute certainty of well integrity

A downhole optical sensing installation typically involves a multi-fibre cable which provides communication from the downhole gauges to the surface instrumentation. Such cable is normally of a fibre in metal tube (FIMT) construction, where the outer diameter is a ¼” steel tube. Sealing of this ¼” tube as it passes through downhole packers, tubing hangers and the like can be readily and reliably done using industry standard compression fittings.

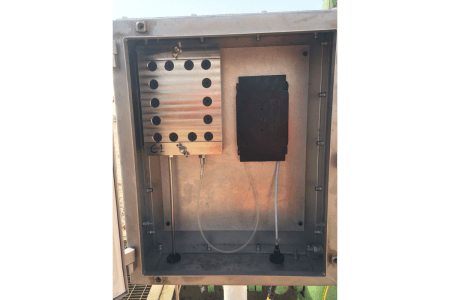

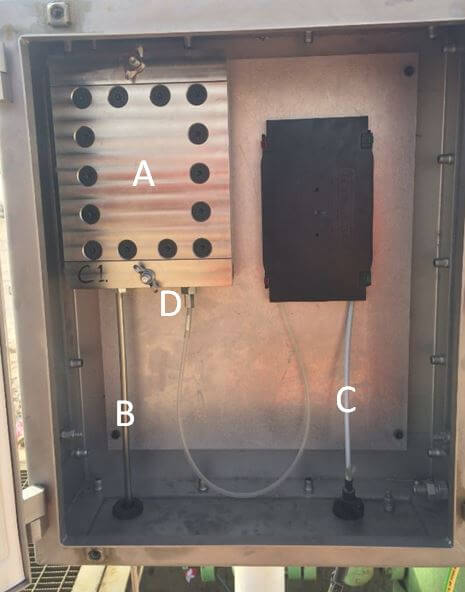

However, there sometimes remains a concern as to whether well fluids may have the opportunity to escape to the surface through the inside of the FIMT in the case of a compromise of the tube integrity downhole. Whilst the FIMT offers a gel filling around the fibres which significantly reduces the likelihood of such a leak to the surface, SmartPB is offered as a surface pressure barrier to provide absolute certainty of well integrity. SmartPB comprises a pressure-tight housing (A) within which spliced or connectorised joining of the fibres from the downhole cable (B) to the surface fibres (C) can be made. A pressure barrier (D) is made around the surface fibres so that, in the event that well fluids reach the surface through cable (B), they are contained within housing (A). Optionally, a pressure gauge is provided as a visual indication that the housing has been pressurised.

Features:

- Surface Pressure Barrier

- Ensures well integrity for downhole optical monitoring installations

- Supports multiple fibre counts and fibre types

- High pressure rating