FAQs

Here you will find some of the more frequently asked questions we receive from our customers. If you have a question that is not covered here, please contact us.

FAQ. How reliable are FBG sensors?

Optical fibre fatigue reliability is very high and FBG sensors benefit from this fact. For instance, client tests found that Smart Fibres’ SmartPatch sensors were still 100 % functional after 6 x107 cycles of tensile and compressive fatigue loading.

FAQ. What software is supplied with an FBG interrogator?

All of our interrogators are supplied with our standard SmartSoft suite of LabVIEW based applications.

For further information about SmartSoft please visit our SmartSoft Software Product Page via the below link.

For options about customising the software, please refer to our further FAQ below.

FAQ. How do I choose the correct fibre coating and FBG recoating?

Please refer to the table below as a guide.

For strain measurement we recommend to use a Polyimide recoat over the FBG due to its superior strain transfer properties.

| Measurement and environment condition | Recommended fiber coating and re-coat material |

| Strain measurement > 85 °C | Polyimide coated fiber with Polyimide recoat (P/P) |

| Strain measurement < 85 °C | Acrylate coated fiber with Polyimide recoat (A/P) |

| Temperature measurement > 85 °C | Polyimide coated fiber with Polyimide recoat (P/P) |

| Temperature measurement < 85 °C | Acrylate coated fibre with Acrylate recoat (A/A) |

Please Email Technical Support or call +44 1344 484111 if you need more help on this point.

FAQ. Does Smart Fibres offer after sales support?

Yes, we offer free telephone and email support to our customers.

Please Email Technical Support or call +44 1344 484111.

FAQ. Why do you recommend using an FBG with a >0.5 nm FWHM for SmartScan instruments?

The algorithm embedded in the SmartScan needs several laser tuning points to overlap the reflection shape of the FBG. In order to achieve a non-linearity error compatible with the SmartScan Specifications, we recommend to use FBG with an FWHM between 0.5 and 1 nm.

Narrower FBGs can be used, at the expense of reduced linearity.

Please Email Technical Support or call +44 1344 484111 if you need more help on this point.

FAQ. Do you have a procedure for mounting FBG sensors onto a substrate?

Yes, please send your request to [email protected].

FAQ. Can we put different sensor types on the same fibre?

Yes, Smart Fibres’ WDM products allow the user to combine different sensors types, e.g. temperature, strain and vibration all on a single fibre.

FAQ. What is the warranty period for Smart Fibres' interrogators?

All of our fibre optic interrogators come with a standard one year warranty. This warranty can be increased on a year by year basis. Extended warranty is available at the time of initial purchase on request.

FAQ. Which length of FBG should I select for my application?

Longer FBGs have a higher reflectivity, but are narrower in wavelength. Our SmartScan instrument range is optimised for best accuracy and resolution with 2 mm or 5 mm FBGs. SmartScope instruments can accommodate narrower FBGs and fiber optic sensors with different spectral features.

You may need to choose the length of the FBG based on the size and strain distribution of the substrate you are planning to measure. E.g., choose a FBG smaller than the substrate length. Also, if there is a strong strain gradient where you want to measure, a shorter FBG is better because the reflection peak of a longer FBG is more likely to become distorted and hard to measure.

Please Email Technical Support or call +44 1344 484111 if you need more help on this point.

FAQ. What is the minimum and maximum distance between FBGs on an FBG array?

FBGs can be spaced anywhere on the fibre greater than 1.5 mm apart.

FAQ. Under which conditions are FBG wavelengths normalised? i.e., if I order a FBG with 1550 nm reflective wavelength, at what conditions will it reflect the 1550 nm wavelength?

Nominal wavelengths are at room temperature, unloaded. The exact value depends on manufacturing tolerances –typically +/- 0.3 or 0.5 nm.

FAQ. How do I compensate for the thermal effect on the strain measuring FBG?

We recommend that a second FBG, which is completely isolated from strain, is fitted close to the strain measuring FBG. Temperature compensation can be achieved in 2 methods, loose FBG or a strain isolated coupon with a known CTE. Our SmartSoft software includes a utility to automate this temperature compensation process.

FAQ. What fibre type is used in your systems?

Single mode fibre with a 9 µm core, 125 µm cladding, and a 155 µm Polyimide or 245 µm Acrylate coating. Optical Fibers with pure silica core, bend tolerant and small core e.g. 6/125 or 4/125, can also be used but with some optical power losses. Multi mode fibre cannot be used.

FAQ. What communications protocol options are available for Smart Fibres interrogators?

For data transmission we can offer Ethernet, CANopen, Modbus/TCP, Modbus/RTU and Profibus DP but not all are available on all our interrogator models.

Please note that some communications protocols will limit the acquisition rates of the instrument, e.g., CANopen is up to 250Hz.

FAQ. How do I calculate which wavelength to use for my FBGs to maximise the number of sensors on a particular channel?

Smart Fibres has created a wavelength budget calculation tool for FBG wavelength selection.

Please Email Us or call +44 1344 484111 with details of your application and we can help you create a wavelength budget.

FAQ. Can you recommend a PC specification for use with Smart Fibres' interrogators?

Generally speaking the faster the processor speed and the newer the processor technology the more likely it is to cope with the speed of data. Nearly all new off-the-shelf laptops and desktops would be fast enough, and these typically have an i3 with a processor speed of 2 GHz or better. Older desktops with Intel Duo ~3 GHz processors are also fast enough.

FAQ. Can I make changes to the software supplied or write my own software to control a Smart Fibres FBG Interrogator?

There are four options for customising the SmartSoft interface software of our instruments:

Option 1) Write your own LabVIEW plug-in

Option 2) Write your own custom LabVIEW interface

Option 3) Write your own custom interface in another programming language

Option 4) Request Smart Fibres to customise SmartSoft to your specific requirements

Email Technical Support or call +44 1344 484111 for more information.

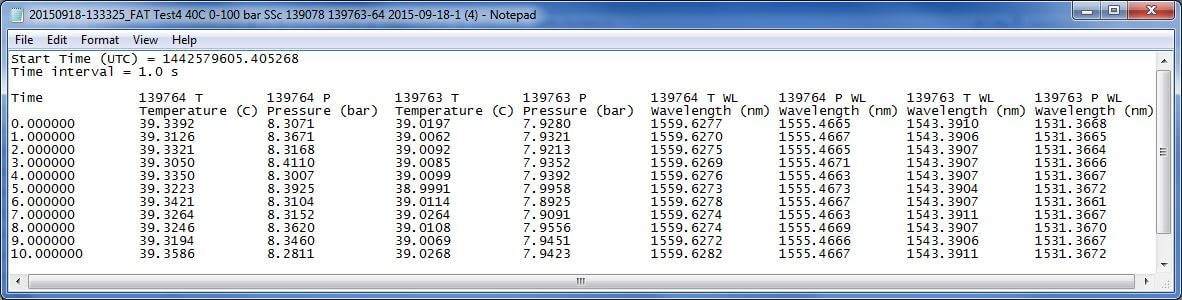

FAQ. Can I synchronise SmartScan data with data from other types of measurement system?

All data from SmartScan is transmitted with a Universal Time Coordinated (UTC) time stamp. The SmartScan’s UTC time is synchronised with the host PC’s clock every time SmartSoft connects to the interrogator. Therefore SmartScan data can be synchronised with time stamped data from other measurement systems.

FAQ. Is it possible to check or change the IP address of the instrument via a RS232 connection?

Yes. Please contact us at Email Technical Support or call +44 1344 484111 for the connection procedure and assistance.

FAQ. Can we connect to the RS232 port for live measurement data?

No, the RS232 port is only used for diagnostics connection.

FAQ. How many optical splitter/combiners can be used in a single channel?

Our instruments have a dynamic range of 27 dB optical power. The table below gives a rough estimate of each device’s loss.

When using low reflectivity FBGs such as drawtower gratings the optical power budget is reduced from 27 dB to 11 dB.

| Device | Optical loss |

1 x 2 coupler | 6db |

1 x 4 coupler | 12db |

1 x 8 coupler | 18db |

FC/APC Uniter | 1db |

FAQ. Is data averaging done on the instrument itself?

No on-board averaging is done. Averaging is done in SmartSoft on the PC connected to the instrument.

FAQ. How can I convert the UTC time stamp to a date & time?

There are three ways:

- Smart Fibres can provide an executable app which runs with the LV8 RTE.

- Use a website conversion tool like: http://www.epochconverter.com/

- Work it out with a calculator, don’t forget to count leap days!

FAQ. Is it possible to log SmartScope data via the USB connection?

No. The USB is not active on SmartScope.

FAQ. Can you set the time reference in the interrogator?

Yes, the time can be set manually using the web browser interface, instructions in section 2.5 of the Manual Addendum for On-board Storage that is included on the disc.

FAQ. How do I calculate the size of USB stick needed for my data?

Three parameters are needed to calculate the length of data that can be stored: disk size, acquisition rate and number of FBG.

For SmartScan USB data is stored in a raw format.

For 32 FBGs at 2,500 Hz, 100 minutes of data can be stored per GByte of disk space; this can be scaled proportionally to number of FBGs or acquisition rate.

E.g., for 16 FBGs at 2,500 Hz, 200 minutes / GByte

E.g., for 32 FBGs at 500 Hz, 500 minutes / GByte

E.g., for 16 FBGs at 250 Hz, 2,000 minutes / GByte

For SmartScope, data would likely be processed into measurement units, so it would be in the same format as files saved by SmartSoft, in which case each measurement uses 10 bytes, plus 10 bytes for the timestamp.

E.g., 32 FBGs = 330 bytes per sample

E.g., 16 FBGs = 170 bytes per sample

E.g., 1 FBG = 20 bytes per sample

E.g., 32 FBGs at 5 Hz = 10,000 minutes / GByte

E.g., 16 FBGs at 5 Hz = 20,000 minutes / GByte

E.g., 32 FBGs at 1 Hz = 50,000 minutes / GByte

E.g., 1 FBG at 1 Hz = 800,000 minutes / GByte or about 18 months / GByte

FAQ. Is it possible to upgrade the sensor capacity on the Modular SmartScan by increasing the number of channels?

Yes, the Modular SmartScan architecture is designed so that the user can increase the number of channels to 8, 12 or 16 by adding additional modules. Please contact us for upgrade options available.

FAQ. Can SmartScan synchronise to a National Time Protocol (NTP) server?

SmartScan can synchronise to a NTP time signal via its Ethernet port.

In this scenario SmartScan would need to be connected on a Local Area Network (LAN) and would also need to be able to access an NTP server, either on the same LAN or over the Internet.

All the data from SmartScan is time stamped, so if an NTP signal is received the timestamps would be synchronised to that signal. See “Plug-in for NTP synchronisation” in the SmartSoft user manual.

FAQ. What is supplied with a SmartScan SBI?

We supply a Linux kernel, driver and root file-system (compatible with the SBI PM), and a documented library of C functions for interacting with the kernel driver. We also supply SmartSoft Application Software and a user manual.

FAQ. Can a SmartScan FBG interrogator be operated as a standalone datalogger?

Yes, any SmartScan interrogator can initially be configured with a PC and then disconnected to log the measurement data to a USB solid state storage device or, in the case of SmartScan Aero Mini, it's onboard flash memory.

FAQ. Can I increase the SmartScan scan rate higher than 2.5 kHz?

Yes, the scan rate is user definable in the SmartSoft software. Table below gives an indication of the scan rates available:

| Scan Rate (All channels simultaneously) | Scan Bandwidth |

2.5 kHz | 40 nm |

5 kHz | 20 nm |

10 kHz | 10 nm |

20kHz | 5nm |

FAQ. Can the acquisition system make a measurement at a fast scan rate and then average these values over a longer time period?

Yes, SmartSoft software has the functionality for the user to set both the scan rate and averaging rate. This will reduce the number of data points being logged to file.

FAQ. What does the message 'data buffer full, losing data' mean?

It means the PC being used is not able to handle the data at the selected speed - there are a few things that can be done to improve the data capturing:

1) In the Instrument Set Up panel > Acquisition Rate tab, configure the number of Channels and FBGs/Channel that are actually connected. If you leave it as the defaults (4 Channels and 16 FBGs) then the interrogator will pad the data messages with zeroes.

2) If just wavelengths are being logging then Basic Acquisition could be used. SmartSoft will perform less processing than in Enhanced Acquisition because it doesn't need to check the coefficients set up in the Sensors table.

3) Use a PC with higher processing power. It can be tricky to assess but generally the faster the processor and the newer the processor technology the better.

Please Email Technical Support or call +44 1344 484111 if you need more help on this point.

FAQ. How do I find the FBG on the fibre?

The typical marking scheme is two black marks per FBG, which are about 10 to 15 mm apart. The FBG is within these marks.