SmartPort

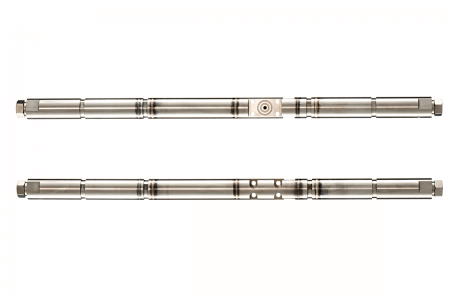

SmartPort is a low profile ¾″ fibre optic P/T gauge. Pressure is communicated via a small pressure port on the gauge body to SmartPort’s novel internal optical sensing mechanism where pressure and temperature measurements are made using two fibre Bragg grating sensors. Annulus pressure and temperature are simply measured by leaving the pressure port open to the wellbore. For formation pressure and temperature measurements, the low profile gauge can be deployed open hole behind the casing. For tubing pressure and temperature measurements, SmartPort can be attached to a gauge mandrel with the use of dual metal o-ring or c-ring seals. Pressure from alternative locations can be communicated to SmartPort via a tube which seals to the gauge at the mandrel interface.

Multiple SmartPorts can be multiplexed on a ¼″ downhole cable to which the gauges are sealed using pressure testable swaged connections. Optical connection between SmartPort gauges is made using our ¾″ SmartLink product. Up to 15 SmartPort gauges can be multiplexed on every 2 fibres. So, for instance, 30 gauges can be deployed using a 4 fibre main cable and one downhole ‘Y’ splitter.

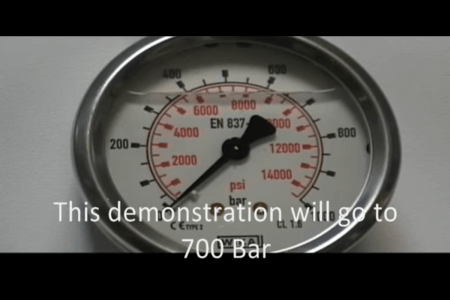

For HT and/or HP application with increased stability, an HPHT SmartPort is under development. Contact us for further details.

Features:

- HPHT fibre optic gauge

- No downhole electronics

- All metal sealing

- Long life at extreme temperature

- High multi-drop capability

- Annulus, tubing or ported pressure configurations

- Low profile ¾” design

- Low cost