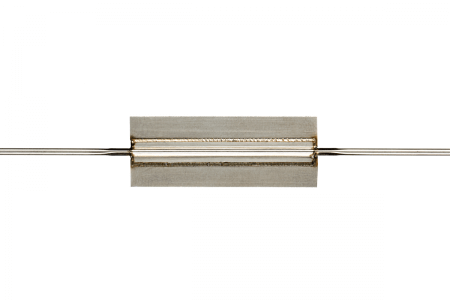

SmartWeld

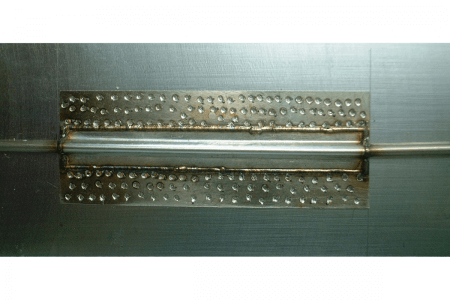

SmartWeld is an optical fibre strain/temperature sensor attached to a thin gauge stainless steel plate. This configuration allows the sensor to be spot welded directly to a steel structure ensuring long-term, creep-free strain transfer, without fear of bondline deterioration. This robust sensor is suitable for demanding environments including civil structures, ship hulls, offshore structures, pipelines, nuclear power plants, bridges and dams.

Features:

- Robust FBG strain and/or temperature sensor

- Can be spot-welded to steel girders, pipes, hulls etc

- Zero power, EMI immune, intrinsically safe

- Multiple km signal integrity

- Suitable for long-term SHM applications

- All stainless hermetic welded construction available for aggressive environments

- Fatigue performance (6 million cycles at +/- 500 µstrain) verified at UKAS testhouse

- Developed for and approved by world–class engineering Company