SmartFBG

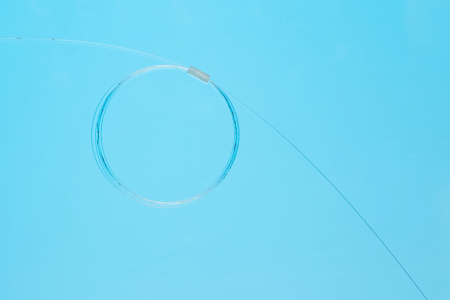

A Fibre Bragg Grating (FBG) is a novel optical sensor recorded within the core of a standard optical fibre. It reflects a narrow bandwidth of light, which responds faithfully to changes in temperature and strain. Many FBG sensors can be recorded onto a single optical fibre and interrogated simultaneously with a single instrument - the effect is a very low cost mechanism for distributed monitoring of strain and/or temperature within large structures, particularly suited to design validation and structural health monitoring.

Features:

- Optical strain and/or temperature sensor

- Zero power, EMI immune

- Intrinsically safe

- Highly stable

- Multiple km signal integrity

- Available singly or in multiple FBG arrays

- Suitable for composite embedment

- Can be used to manufacture smart sensors and transducers

- Suitable for long-term SHM